MAC's masonry education is provided by

Walter A. Laska, President - Masonry Technologies

This learning course is approved for .5 (1/2) AIA or PDH accreditation.

Read this article and answer the 5 questions below to receive credit.

Learning Objectives:

1. Learn what factors to take into account when detailing steel joist-to-masonry connections.

2. Learn how a steel joist-to-masonry connection will provide lateral support of a load bearing wall.

3. Learn how movement affects joist connections and how to accommodate this movement.

4. Learn how successful construction can be assured by developing well developed and workable connection details.

Steel Joist to Masonry Connection

Steel Joist-to-Masonry Connections

The structural composition of a building often consists of masonry walls and steel joists. In this type of system, masonry walls perform as both bearing and nonbearing components. When detailing steel joist-to-masonry connections, designers should take into account several factors, such as the type of the connection, potential movement between the two systems, and lateral bracing of the masonry walls.

K-series and LH-series steel joists are most commonly used with masonry. The span and depth of these open-web joists determine their bearing requirements, as established by the Steel Joist Institute.

K-series joists range from 8 to 30 inches in depth, with a maximum span of 60 feet. The minimum bearing requirement on masonry for a K-series joist is 4 inches, If the joist is detailed to be anchored to a steel bearing plate, the plate must be at least 6 inches wide (parallel to the wall).

LH-series joists range from 18 to 48 inches in depth, with a maximum span of 96 feet. The minimum bearing requirement on masonry for an LH-series joist is 6 inches. If the joist is to be anchored to a steel bearing plate, the plate must be at least 9 inches wide (parallel to the wall).

It is sometimes necessary, however, for a steel joist to bear on masonry less than the required dimensions - when constructing tall, slender (single-wythe) reinforced masonry walls. In such circumstances, the structural engineer should give special consideration to the design of the masonry and steel joist connection.

Bearing and Non-Bearing Wall Connections

Masonry walls must be braced laterally to resist wind loads (which govern in non-seismic areas). This bracing is commonly provided by a roof system constructed of steel joists. The steel joists (and metal decking) act as a diaphragm that continuously braces the wall against wind loads.

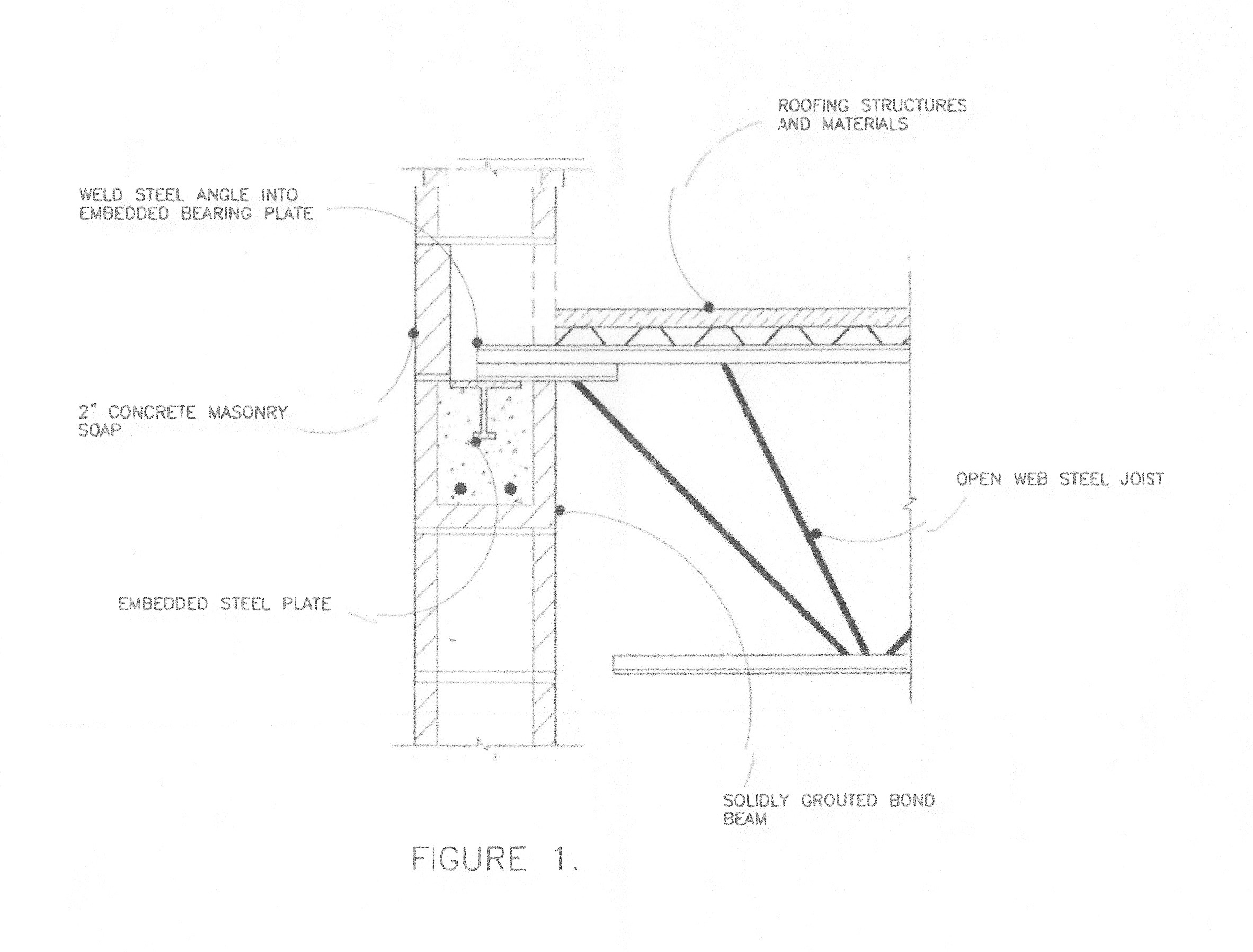

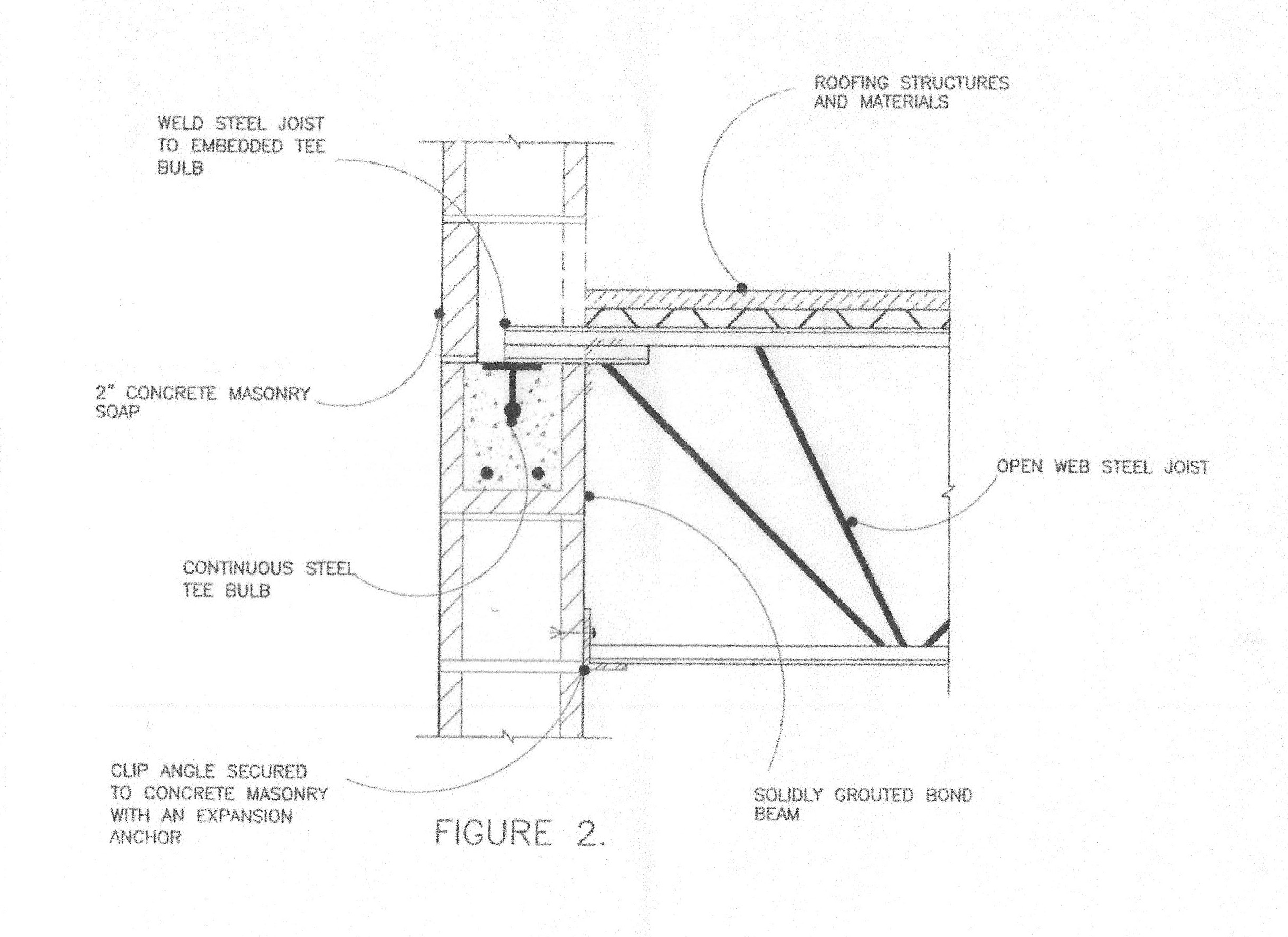

Bearing walls are braced at the masonry and steel joist connection. A bearing wall connection should be designed so that it can be easily installed. This connection needs to be adjustable in two directions, north-to-south and east-to-west, to accommodate construction tolerances. If a welded connection is desired, then a bearing plate with studs should be provided to achieve adequate adjustability (Figure 1) to increase the allowable height of a wall without increasing the wall thickness, the bottom chord of the joist can be extended and connected to the wall—but only after all roof dead loads are in place. This connection will provide lateral support of the wall (Figure 2).

However, the joist must be stiff enough to minimize deflection after live loads are applied. If excessive deflection occurs, a horizontal crack can develop in the mortar joint immediately above or below the bottom chord connection.

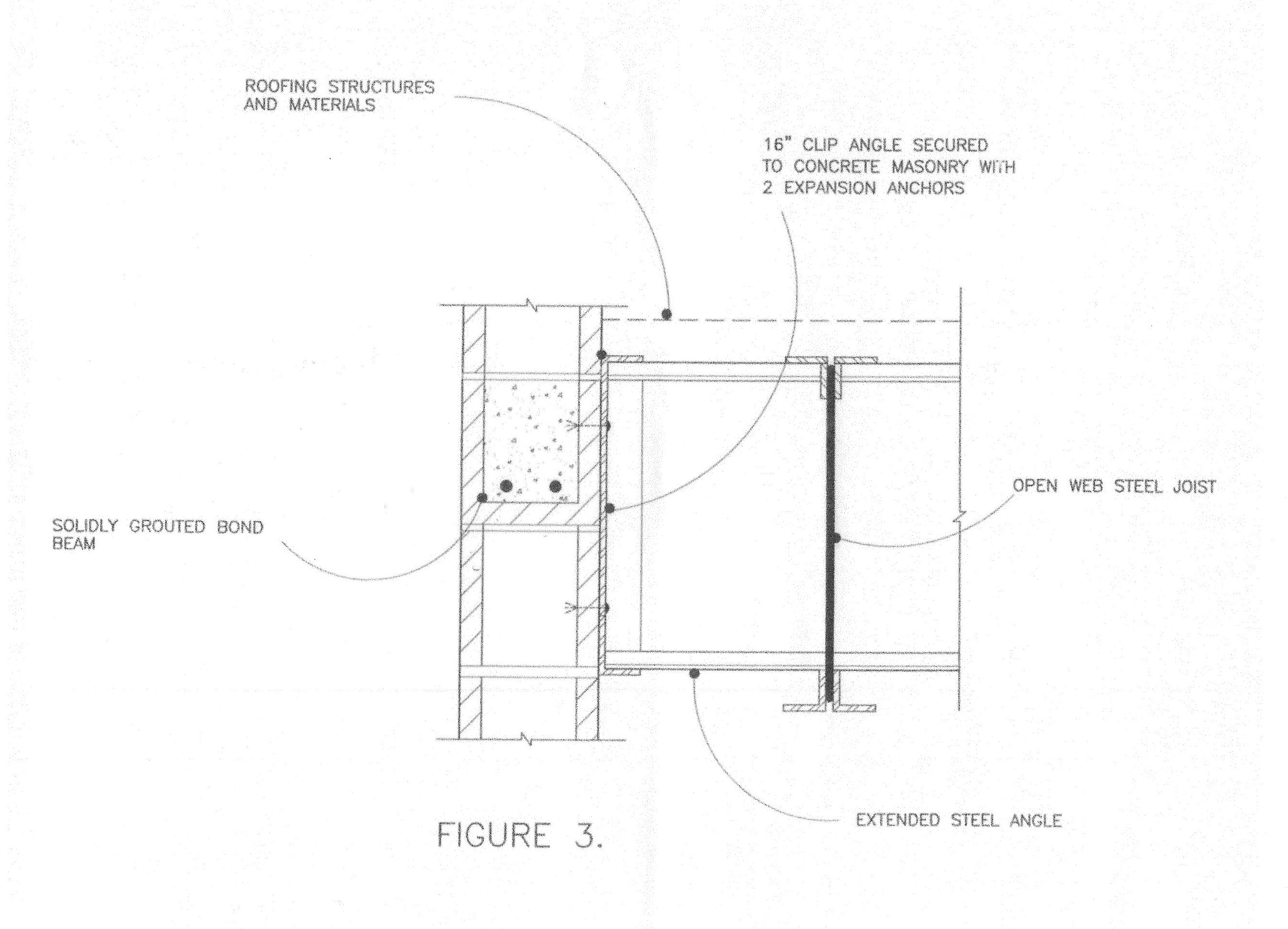

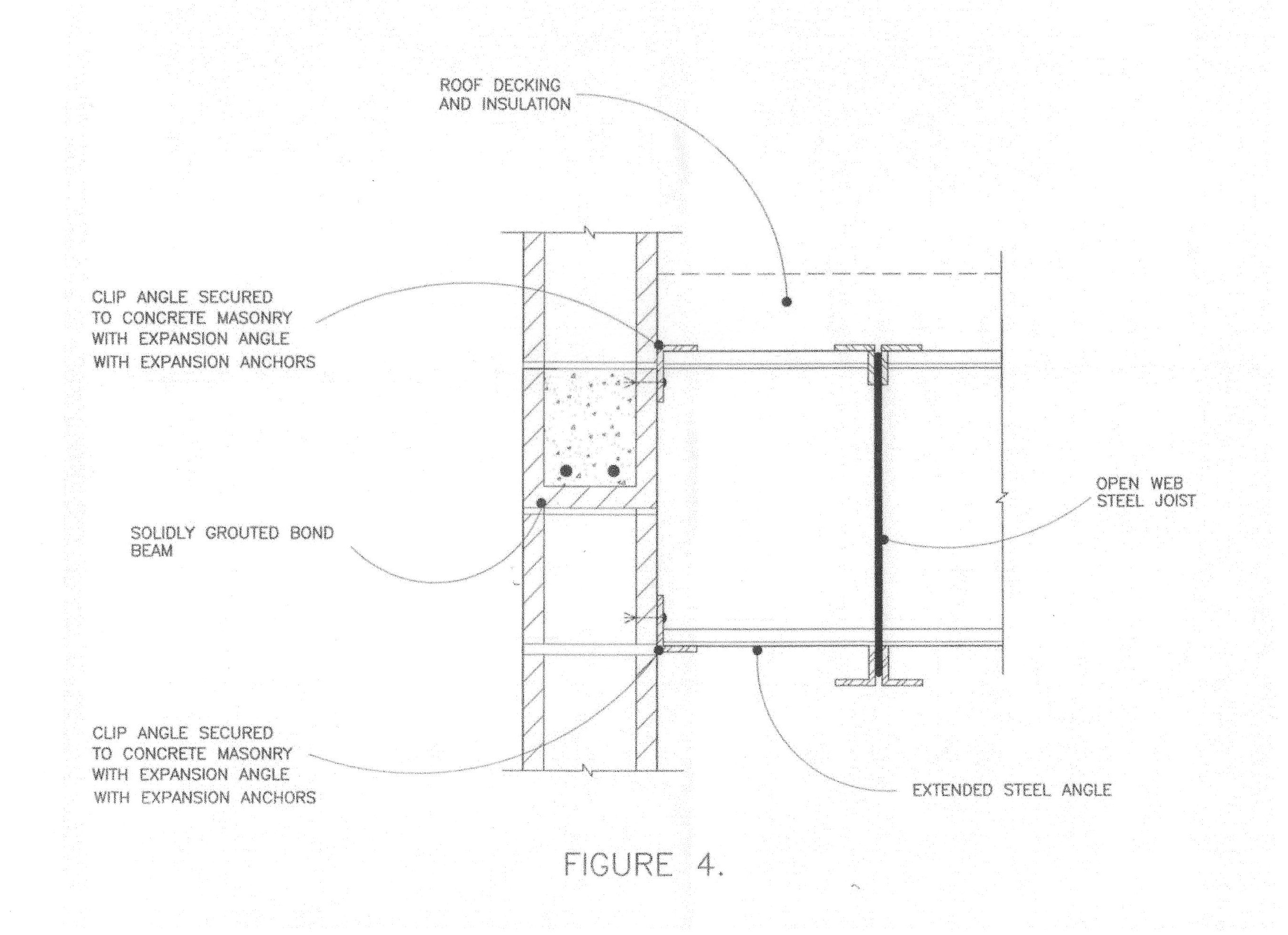

When connecting steel joists to non-bearing masonry walls, connection adjustability is not quite as critical as in bearing wall connections. The connection can be accomplished by extending an angle along the bottom cord of the steel joist and welding it to an angle anchored to the concrete masonry wythe (Figure 3 and Figure 4). Align the extended bridging angles with the horizontal steel joist to prevent crimping in the steel cords due to wind pressure. However, if spacing between the bridging angles is in excess of 6 feet, bridging alone may not adequately transfer wind loads. In this case, you must increase the number of bracing angles.

If diagonal bridging is used between steel joists, specify a horizontal bridging connection at the end of the steel joists to brace the walls laterally. Cross-bracing these joists to the masonry is not recommended and may cause the walls to bow. When the joist deflects, loads are induced into the cross-bracing, pulling the top connection inward while pushing the bottom connection outward, resulting in additional bonding stresses.

Movement

When a roof joist spans its maximum length and carries its maximum allowable load, the ends of the joist will rotate. This inward movement (joist shortening) is the result of defection. If this condition is overlooked, the masonry possibly can bow and crack.

One way to eliminate this problem is to specify joists stiff enough to resist maximum deflection. Deflection can also be minimized by increasing the number of joists, thereby reducing the space and load between them.

Roofs should be insulated properly to prevent joist movement due to temperature variations. It also should consider the time of year the steel joists are erected and the type of enclosed environment they will be subjected to. If steel joists are erected in hot weather and subjected to heavy cooling or refrigeration upon completion, they will contract. Steel joists erected in cold weather and later subjected to heating will expand. To accommodate this thermal movement, the steel fabricator can modify the camber (upward bowing) of the top chord of the steel joist.

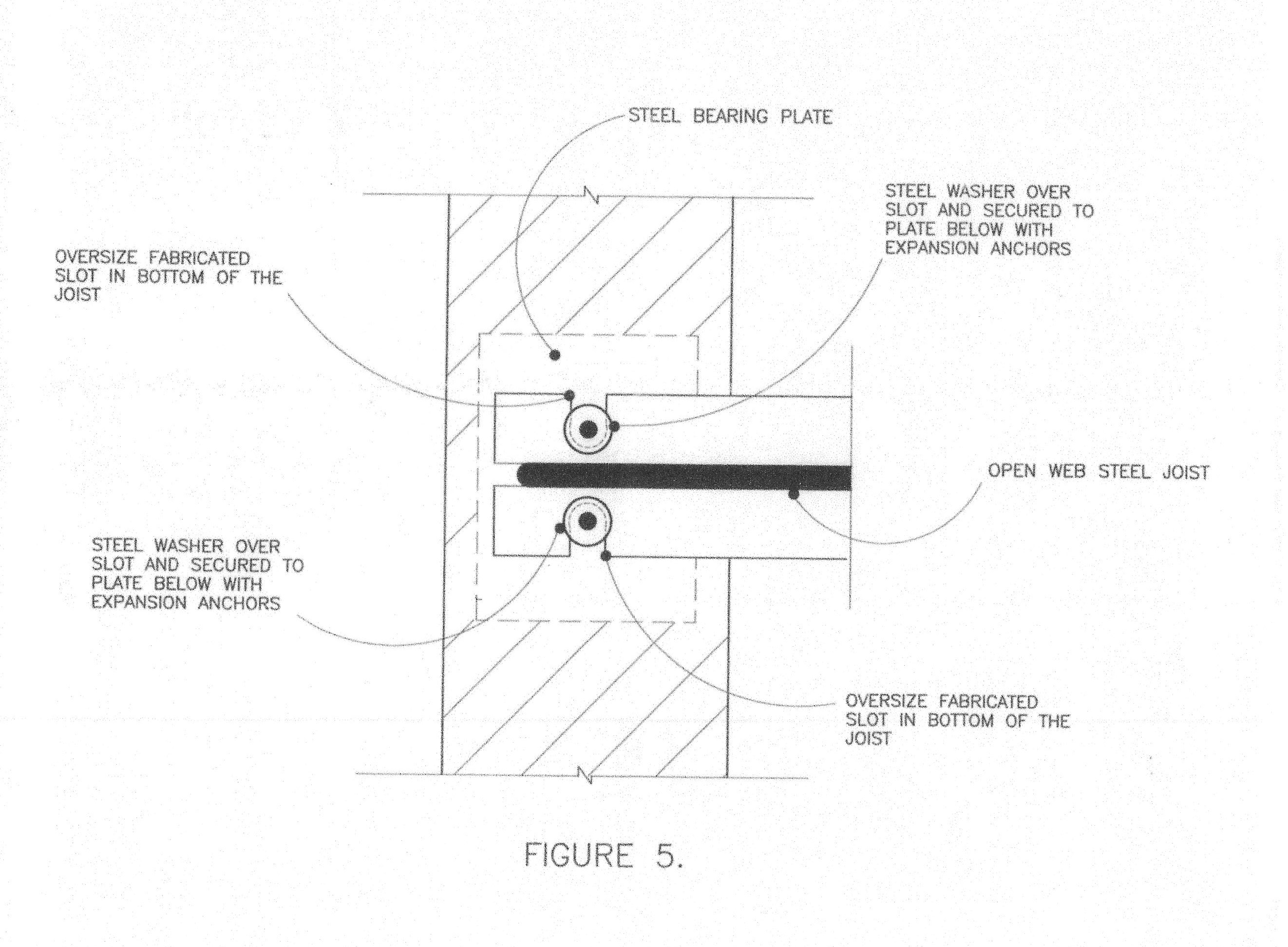

A slippage joint can be created at the steel joist and masonry connection by requiring the steel joists to be slotted at the bearing point. The slotted connection must be oversized to accommodate movement by the steel joist. A washer should be placed over the slot and then an expansion anchor should be installed through the slot and tightened. The anchor should not be fully torqued, as so to allow some movement of the steel joist (Figure 5).

In addition, joists should not be in direct contact with the outer face shell of concrete masonry units or the outer brick wythe. Provide a clearance of ¾ inch. If the two materials are in contact, any structural movement of the joist can stress the concrete masonry, possibly causing cracks on the outer surface of the masonry.

Conclusion

Successful design of masonry and steel requires a thorough understanding of the two materials. Numerous problems can be avoided and successful construction can be assured by providing well-developed and workable connection details.

Answer these 5 Questions to receive your Continuing Education Credit

Thank you! Your answers will be reviewed and an email will be sent to you confirming accreditation.